How much beer do we have?

Speaking to breweries all over the world, keeping track of how much beer they have is one of the most common problems they face. Time is wasted taking inventory over and over and not knowing what products they have available to sell can cost serious money

when orders can’t be fulfilled, as well as the reputational damage that comes with it. In the long term, this is fundamental knowledge and will have a huge impact on the business’s ability to grow. Everyone we speak to agrees that they need a system in place to track all this, whether it’s software or even a detailed spreadsheet – but what information do we need to see?

We took inventory today, that’s enough right?

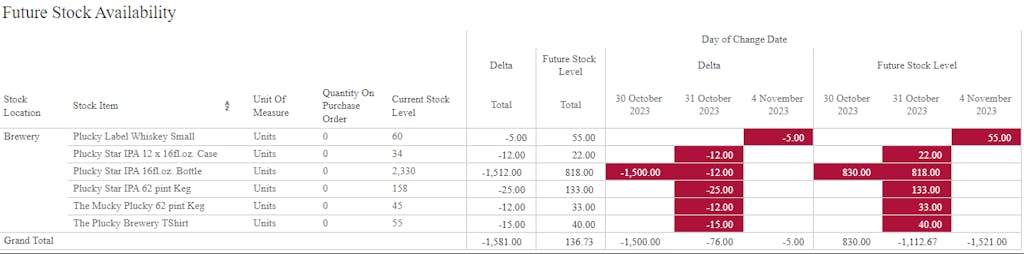

Many breweries take inventory regularly so might feel confident they know how much they have to sell. However, when that call comes in from a customer who orders 6 kegs, it can be difficult to know whether the inventory we have is sufficient. We can look at the

count and see there are 38 kegs in stock but we also know today that 20 kegs are going over to the taproom, 16 are due for dispatch, and we’re going to package 12 more by the end of the day – can we sell the 6 now? This only gets more complicated when

thinking about an order for next week and all the many orders, transfers and brews that will happen between now and then!

Our system of managing inventory needs to make sure that we take all this into account and whichever system we’re using can give us the numbers we need when we need them for today, next week or a month from now.

We know how much we have now, but we’re always running out!

Once we’ve finally solved the problem of knowing how much beer we have, how do we plan ahead to make sure we’ll have enough for our demand? Knowing exactly how much inventory we have available doesn’t solve the problem of running out! However, once we are confident in our data, we can utilize it to forecast and help inform what we should be brewing and when. A common way to do this is looking at sales rates of each of our products over a period of time and comparing to current inventory levels. Now we are able to see which of our products will run out first and this can be vital data to pass on to our brewing team so that our supply always meets our demand.

If these problems sound familiar and you’re looking for ways to solve them, BrewMan provides our users with real-time visibility of all inventory across multiple sites. Our integrations with POS systems and ecommerce software enable this data to sync into one system, giving a single source of truth. If you’d like to find out more, check out a 30 day free trial especially for CBP members at

https://www.premiersystems.com/brewman-usa or get in touch with me at Sam@premiersystems.com

Sam has been Commercial Director at BrewMan for the past five years, speaking to breweries across the world about solving issues through technology.