Is Age Just a Number? What Craft Beer Professionals Should Know About the Accelerated Aging and Shakespeare

Most Craft Beer Professionals probably have a barrel aging program, but perhaps don’t understand the chemical changes occurring in the beer as it quietly sits on a rack. In most cases beer is only aged a couple of months to a year, extreme examples like Sam Adam’s Utopia can be aged for decades. However, is beer required to have birthdays or see multiple Presidential administrations to be

considered “the good stuff”? To borrow from Shakespeare’s famous saying from Romeo and Juliet:

“What’s in a BARREL AGED BEER? That which we call a BARREL AGED BEER

By any other name would TASTE as GOOD.”

Shakespeare was arguing the name of something does not affect what it is and its qualities are not changed by the name we give it. Perhaps could the same be said for beer? Is it possible to develop the same flavors associated with barrel aging more quickly in another way? Is the time important or merely the flavor? Maybe “age” should be like how we’ve trained our 7-year-old son to answer the question, “How old is mommy?” His answer every time is, “Beautiful!”

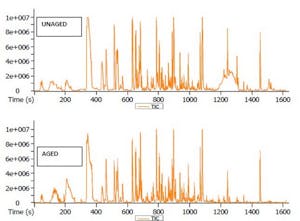

In aging there are complex chemical reactions occurring with new molecules being formed or extracted and other molecules being removed or transformed. Wood flavors are extracted from the barrel (or other former inhabitants of a used barrel), oxidation/esterification reactions form new molecules and impurities are removed through adsorption to charred surfaces. This is easily demonstrated with simple chemical analysis like the GC-MS below showing the disappearance of some peaks and the emergence

of new ones.

Is aging in a barrel the only way to develop these flavors? No, in fact you may already be familiar with some barrel alternatives such as chips or staves. However, you probably haven’t considered cavitation or ultrasound in conjunction with these products. Ultrasound has been known for decades to increase extraction and accelerate chemical reactions. Cavitation and ultrasound are largely similar except cavitation is initiated mechanically while ultrasound is initiated acoustically. Both create pressure fluctuations and microcavitation bubbles in a liquid that continuously agitate the liquid, promoting the chemical reactions associated with aging and increasing the extraction of compounds from the wood.

Example of a brewery cavitation device on right (ShockWave Xtractor by XtractMor)

Ultrasound and cavitation can replicate the complex chemical reactions and flavor development that occur naturally over time in the traditional barrel aging processes. This accelerated aging process can impart a smoother, more complex taste profile to the beer, reminiscent of barrel aging in a fraction of the time, usually minutes rather than months. This can allow breweries to sell these beers immediately with less loss due to evaporation or spoilage.

Maybe age is just a number and maybe all that should matter is taste, ultimately the customer will decide. However, Craft Beer Professionals should be aware of all the options to add aged and oak flavors to their beers to see if barrel aged beer by any other name is still as good.

—

Doug Mancosky is Chief Science Officer and CEO of XtractMor, Inc. of Rome, GA (www.xtractmor.com). XtractMor is a wholly owned brewery focused subsidiary of cavitation pioneer Hydro Dynamics, Inc. He studied Chemistry at St. Norbert College in DePer, WI and obtained his masters and Ph.D from the Institute of Paper Science and Technology at Georgia Tech studying wood chemistry. Doug was

exposed to fermentation at a young age, helping his grandparents pick wild elderberries on public roadsides for homemade wine. He also assisted in the founding of Outrun Brewing Company in Stone Mountain, Georgia. Dr. Mancosky resides in Northwest Georgia with his wife Pam and his son Thomas.