Beer Recovery from Heavy Tank Bottoms

It’s no secret that dry hopping, double dry hopping, triple dry hopping, adjunct additions, and everything else that gets thrown into conical fermenters negatively affects yield. Brewers and cellar people do everything they can to mitigate these losses. But inevitably, there will be lost beer in the form of waste that is dumped down the drain or to a brewery’s wastewater system.

In addition to the beer lost, the solids in the waste are costly to treat onsite or even to send down the city sewer system. What can a brewery do to mitigate these loses and avoid costly sur-charges from excess BOD in the effluent to the city WWTP or brewery water treatment?

A decanter centrifuge system is an excellent way to not only recover the beer lost in the waste from the fermentation process but also to remove excess solids from the wastewater discharge while also reducing the workload on downstream filtration or clarifiers.

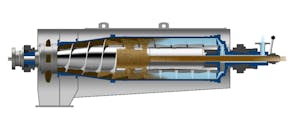

Decanter centrifuges are different from the vertical disc stack type that are typically used for final beer clarification. A decanter is a horizontal machine with a solid rotating drum and a screw that rotates separately inside to convey the separated solids to the discharge. The reason to choose a decanter over a disc machine for this application is that a decanter can separate streams with very high solids content. A disc machine will separate streams with up to 7 or 8% solids, whereas a decanter can separate streams with up to 70 or 80% solids.

A tank bottoms decanter is typically a stand-alone system that is easily integrated into the cellar. It consists of four major components. The decanter itself, the elevation stand with piping and instrumentation mounted to it, the control panel/HMI, and the feed pump. The utilities required are electric, compressed air, Co2, CIP, and flush water connections.

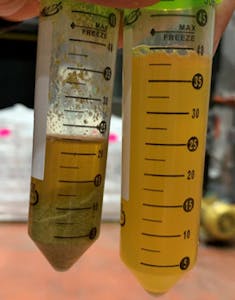

The concept is simple. The heavy sludge in the bottom of the fermenter is pumped into the decanter at a flowrate dictated by the machine size and the solids load. The liquid is separated from the solids in the mid-section of the bowl, and the screw conveys the solids out of the bowl into either a positive displacement pump or into a bin placed underneath the machine.

The separated beer is skimmed out via an adjustable impeller and discharged back to the fermenter under pressure. The system can create up to 28 psi of return pressure and pump the recovered beer up to 100 feet (depending on rise) back to the fermenter.

The return is typically through the racking arm or standpipe. If it is a racking arm, the arm can be moved about a quarter turn every 20 minutes or so to wash the solids from the tank to avoid leaving hops stuck to the side of the cone. The system is purged with a small amount of Co2 to minimize dissolved oxygen pickup, which can be held below 20 parts per billion.

The system is designed to be hygienic and has an automated CIP sequence that completely cleans it. A wide range of instrumentation is available to monitor conditions, such as inlet and outlet dissolved oxygen content, flow rate, and total volumes to and from the machine, inlet and outlet turbidity, and Co2 consumption to name a few.

Any brewery that is struggling with heavy losses from dry hopping and/or issues with BOD in their wastewater could benefit from a tank bottoms decanter system. With a small footprint, low installed horsepower, and short ROI, it has been a game changer for some of the most popular U.S. breweries.

Christian Pettit is the sales manager for Brewing, Distilled Spirits and Wine for Flottweg Separation Technology Inc., located in Independence, KY. Christian has a background in CNC machining as well as electrical/mechanical maintenance and process development. He holds a mechanical engineering degree and has over 15 years of centrifuge experience, including stints in the service department, process engineering and sales.